NEWS

Advancing High-Temperature Applications with Composite Non-insulated Refractory Glass

Published:

2023-07-07 15:13

Author:

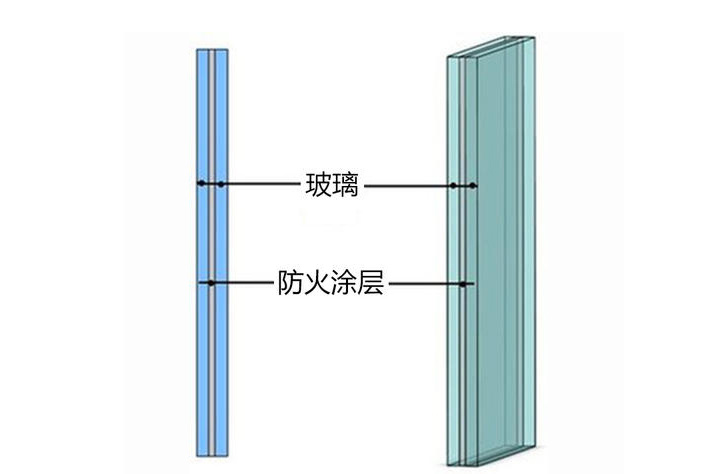

Composite non-insulated refractory glass is paving the way for cutting-edge solutions in high-temperature applications across various industries. This innovative material combines the strengths of composite materials and refractory glass, opening up new possibilities in thermal management and insulation.

The composite non-insulated refractory glass is specifically engineered to withstand extreme temperatures, making it ideal for use in furnaces, kilns, and other industrial thermal processes. This advanced material exhibits remarkable thermal stability and can endure rapid temperature changes without compromising its structural integrity.

One of the key benefits of this composite material is its superior thermal insulation properties. The refractory glass component minimizes heat transfer, ensuring that the surrounding environment remains unaffected by the high temperatures within the application. This not only improves energy efficiency but also enhances safety by reducing the risk of thermal damage to surrounding equipment and structures.

In addition to its exceptional insulation capabilities, the composite non-insulated refractory glass offers exceptional mechanical strength and durability. It can withstand the harsh conditions of high-temperature environments, including thermal shocks, corrosive gases, and rapid temperature cycling. This robustness ensures a longer service life and reduces maintenance requirements, resulting in cost savings for industries relying on these materials.

Furthermore, this innovative composite material is engineered to have a low thermal expansion coefficient. This reduces the potential for thermal stress and cracking, ensuring reliable performance even under extreme thermal conditions. The precise control over the material's expansion and contraction provides stability and extends the lifespan of the application.

Industries ranging from steel manufacturing to glass production and aerospace are embracing the advantages of composite non-insulated refractory glass. Its versatility and adaptability make it suitable for a wide range of high-temperature applications. Additionally, the material can be customized to meet specific requirements, such as shape, size, and thermal conductivity, for seamless integration into existing systems.

As technology continues to evolve, the demand for materials capable of withstanding higher temperatures will only increase. The composite non-insulated refractory glass represents a significant step forward in addressing this demand, offering enhanced thermal management and insulation in extreme environments.

In conclusion, composite non-insulated refractory glass is revolutionizing high-temperature applications with its exceptional thermal insulation, mechanical strength, and durability. This advanced material provides industries with a reliable solution for managing extreme temperatures while promoting energy efficiency and safety. As industries continue to push the boundaries of high-temperature processes, composite non-insulated refractory glass will play a crucial role in enabling their success.

Keywords:

Composite Non-insulated Refractory Glass

Related News